3D printing is complicated. There are many moving parts. It is important to have the right tools and equipment. The best 3D printer is fantasticHowever, you will also need to have specific software in order to print a 3D model. These programs, known as slicers are crucial for making your 3D printer actually 3D print.

What is a slicer?

Slicer software can be used on your Mac or PC to convert 3D models files. It is usually a program that has the file extension.STL.3MF.OBJ. This allows you to make them usable for your 3D printer. A printer is basically a complex plotting machine that moves to coordinates specified by the slicer using something called GCODE.

Slicers do exactly what they sound like: They cut 3D models into smaller “sliced” layers, which are printed separately but stacked on top each other. Slicers are also responsible for:

- What temperature should the printer be?

- How fast the printer should move

- What place should the supports be placed on the model?

- What amount of infill is needed for the model?

- Where the printhead should be in any given second

- How much material should I extrude into each layer?

- There are many other settings that can also be adjusted

The slicer basically tells your printer everything it needs to work, and it’s the most important piece you have.

Once we have a basic understanding of what a slicer does we can now discuss the best ones. We will decide which slicer to use. What kind of 3D printer do you use? What you will use it for. Different slicers are required for resin printers than FDM machines. This article will explain which one.

The best 3D printing slicer

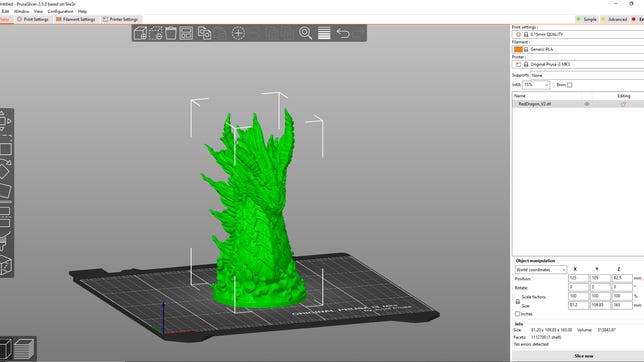

James Bricknell / CNET

PrusaSlicer offers FDM printers the best slicing experience. Although it’s made by 3D printer manufacturers, PrusaSlicer is not proprietary to Prusa printers. It also has a wide range of printers. There are ways to make a customized setup for any 3D printer if your printer isn’t listed.

Prusaslicer has many outstanding features, but the support system is what really stands out. PrusaSlicer’s paint-on support allows you to draw exactly where you want them to go, and they only create in those areas. This allows for fine control over where the model supports itself, so it doesn’t get damaged by printing.

Although this slicer supports resin printers, it currently only supports Prusa’s machines. However, it allows you to export your edited model (completely with supports) to another slicer if necessary.

Prusa slicer is feature-rich and well-maintained. It’s also constantly improving in new and exciting ways. This slicer is the best available right now, and it should be in your rotation.

James Bricknell / CNET

Cura has been the go-to slicer of choice for millions for almost a decade. It is continually updated and improved upon by Ultimaker, the original creator, as well as hundreds of other users who actively contribute to the open source code base. It is also used by 3D printing companies as the base of their branded slicers which often come with 3D printers.

Although Cura’s fill system is heavier than Prusaslicers it still features tree supports. These supports, which are organic in appearance, can support a model without affecting the object’s physical form. They are very thin and don’t require much material to wrap around the model. Prusaslicer supports are still my favorite, but I prefer tree supports.

Cura offers a marketplace where you can purchase add-ons from the community. There are also integrations with CAD programs like Autodesk Inventor. Prusaslicer is the better free slicer. Cura is close behind.

James Bricknell / CNET

For as long as I’ve used a resin printer, Chitubox was my preferred slicer for printing resin. There are many similarities between FDM and resin slicers. However, the most important difference is the ability of hollowing your models and how the supports are designed. The support structures for resin prints must be placed differently because they are hung upside-down.

Chitubox makes it easy to adjust the settings of each model, as well as the resin used, in order to account for speed or exposure time. There are many printers to choose from. Chitu also makes motherboards.

Although there are both paid and free versions, most home users can use the free version. You might be able to get the pro version for free when you purchase a resin printer.

James Bricknell / CNET

Most slicers need to be downloaded onto your Mac or Windows PC. Kiri.Moto can run on any browser. This allows you to use lower-end laptops, and save money on 3D printers.

Kiri:Moto can also handle the Creality CR-30 conveyor printer with ease. In fact, Kiri:Moto was a key member of the team that helped push conveyor belt slicers forward in the early days.

This simple slicer has many powerful settings. It can be accessed from almost anywhere and on any device. It works even on my Android phone! That’s truly unique.

James Bricknell / CNET

Lychee is a popular resin printing material and it has been for many years. It does everything Chitubox could do. However, it has clever settings that will help you choose the best orientation for your printed to reduce the support required. It is versatile resin slicer that has been updated to its best yet.

Lychee just added FDM printers to its slicer. Now you can use one slicer to print almost any printer. It contains profiles for almost every name in 3D printing, including the Ankermake M5, an extremely new printer that is only available to preorder.

Lychee’s most powerful tools are hidden behind a paywall that can cost up to $80 per annum. However, if you plan on using your 3D printer for business purposes, this outlay is reasonable. The Pro version now includes a new tool that allows you to cut your models in precise ways without having to go through the entire model. This is something that’s not been done before. This is a remarkable feat that’s well worth the annual cost.

James Bricknell / CNET

It was a huge leap forward in 3D printing when Simplify3D came out in 2013. It was a great slicer. It was intuitive and had some of the best support in the industry. It was quite good when I first used it in 2017, but it had not seen much improvement and other slicers were beginning to catch up. Although it was still capable of producing great prints and supported well, there weren’t many new machines available. Also, support disappeared.

Simplify3D 5.0 was released in December 2022. The new version includes many new features as well as support for several new printers. It may be time to make a comeback. Although the company has a long way to go before it can win back customers, I’m impressed with the software.

If you have owned Simplify3D before, you can get 5.0 for $60. But if it’s new, you will need to pay $200. This is a lot of money for a slicer. But, if you believe the rumors about 5.0, it may be worth it.

FAQ: 3D printing cutter

Can any slicer be used with any 3D printer?

Although many slicers can be used with different machines, they are not all compatible. It would be impossible to create a universal slicer that works with every 3D printer. However, most slicers can be set up to allow the creation of custom machines. You should be able use the slicer as long as it is compatible with your printer type (FDM, Resin or ETC).

Prusaslicer, Lychee and Lychee can be used with FDM and Resin printers.

Why do you place so much emphasis on support?

After testing many different slicers, I discovered that the way they handled support material had the greatest impact on print quality. While most slicers share the same capabilities, such as speed control and infill patterns, each slicer has its own way of making supports.

Supports can be a major problem for 3D makers. It is important to find a slicer that can easily make them.

Do I need to use the slicer included with my 3D printer or should I just keep it?

3D printers often come equipped with their own slicer. Most often, the slicer is based on Cura, an open-source Cura platform. You will know that the brand slicer for any Elegoo, Creality or Anycubic printer is based on Cura, with minor modifications.

Problem with using a brand-stamped copy of a slicer, is that they can be slow to upgrade. Cura is frequently updated very quickly, and many 3D printing companies don’t want to spend the money to upgrade it.

When testing products, I use the brand version. However, my personal prints are usually done on Prusaslicer and Cura. I like cutting-edge and Cura gives it.