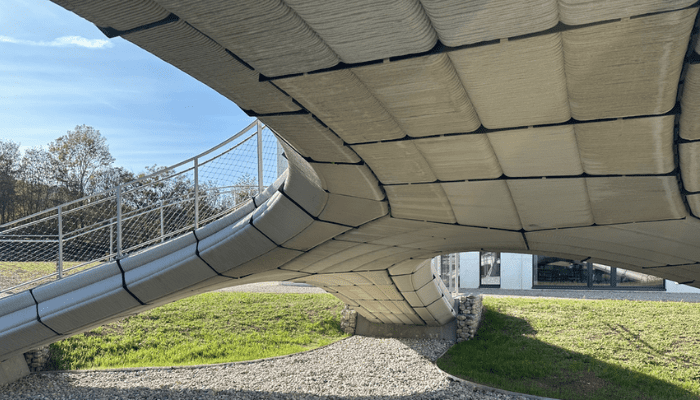

Additive manufacturing is remodeling and revolutionizing building strategies, opening up new potentialities when it comes to effectivity, customization and sustainability in a always evolving business. Holcim, an organization specializing in concrete 3D printing, has lately accomplished the development of the “Phoenix” bridge. This 3D printed concrete bridge is the results of a fruitful collaboration with famend companions such because the Block Analysis Group of ETH Zurich, the Computation and Design Group of Zaha Hadid Architects, and Incremental3D. This collaboration has performed an important function within the seek for sustainable infrastructure options for the Phoenix venture.

The creation of the Phoenix Bridge benefited partially from the recycling of aggregates from the unique Striatus blocks, the primary of the reinforcement-free 3D printed concrete bridges to be unveiled on the Venice Structure Biennale in 2021. Constituted of 10 tons of recycled supplies, the bridge was molded utilizing a mix specifically designed by Holcim, modifying its composition to cut back its carbon affect by 40%. This enchancment interprets right into a 25% discount within the construction’s whole carbon footprint. Edelio Bermejo, head of analysis and growth at Holcim, underlines the ecological significance of the venture, stating that Phoenix “[is] demonstrating that important infrastructure could be designed and inbuilt a method that’s round and low-carbon at present.”

Round building strategies, together with 3D printing, can scale back the usage of supplies by 50%.

This bridge highlights the advantages of a extra environmentally pleasant infrastructure, characterised by the truth that Holcim has developed a particular combine for the concrete of the Phoenix bridge utilizing its round ECOCycle® know-how. The particular concrete combination incorporates recycled supplies from constructing demolitions with absolutely recycled ECOPlanet cement. Because of round building, which mixes computer-aided design and 3D printing, it’s potential to cut back the usage of supplies by as much as 50% with out compromising efficiency.

Philippe Block, co-director of the Block Analysis Group at ETH Zurich, explains: “Concrete is a man-made stone, and like stone, it doesn’t need to be a straight beam, it needs to be a masonry arch. Following these historic ideas permits us to maintain supplies separated for simple recycling and to dry-assemble the construction for simple deconstruction and reuse. 3D concrete printing permits us to make use of materials solely and precisely the place wanted. The result’s a sustainable and actually round method to concrete building.” Johannes Megens, co-founder of incremental3D additionally notes, “Now, after two years and in its second iteration, Phoenix provides a largely diminished carbon footprint and permanence in keeping with constructing codes together with many different additional enhancements.”

By utilizing Holcim’s round ECOCycle® know-how, the corporate and its companions at the moment are exploring alternatives to increase the affect of Phoenix right into a wider deployment of sustainable infrastructure options. To be taught extra in regards to the Phoenix bridge, you may go to Holcim’s web site HERE.

What do you consider the Phoenix Bridge? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly E-newsletter right here, the most recent 3D printing information straight to your inbox! You too can discover all our movies on our YouTube channel.

*All photograph credit: Block Analysis Group