– The Politecnico di Milano is main a world consortium devoted to bettering useful resource effectivity within the building and automotive sectors by means of metallic 3D printing.

—It’s hoped that additive manufacturing expertise will assist usher in a brand new period of elevated customisation and optimisation, permitting firms to scale back waste and power consumption in the course of the metal manufacturing course of.

Based on the European Fee, round 30% of all waste produced throughout the European Union annually comes from the development and demolition business.

That is why one worldwide analysis challenge, coordinated by the Politecnico di Milano, is targeted on lowering the sector’s carbon footprint, together with that of the automotive business, by means of progressive metallic 3D printing expertise.

ConstructAdd financed by the Analysis Fund for Coal and Metal, is bringing collectively firms alongside expertise and analysis centres from 5 European international locations to enhance useful resource effectivity within the metal manufacturing business.

“The principle goal of ConstructAdd is to deliver metallic 3D printing expertise into the mainstream of the development and automotive industries,” explains challenge coordinator Dr. Alper Kanyilmaz. “Why? As a result of the present targets of each governments around the globe, and society as a complete, are lowering carbon emissions and coping with waste issues.”

“These issues, that are main challenges for the development business specifically, can’t simply be solved with standard methods, just because standard methods had been invented for issues of the previous.”

Particularly, ConstructAdd goals to show that the introduction of metallic 3D printing can create much less waste throughout fabrication whereas additionally lowering power consumption by roughly 30%.

Together with the Politecnico di Milano, challenge companions in ConstructAdd embody the College of Pisa, RWTH Aachen, Prima Industrie S.p.A., BLM Group, Det Norske Veritas, CIMOLAI SPA, VALLOUREC, MIMETE, ArcelorMittal Vitry and IMDEA Supplies Institute.

“Given round one-third of all of the waste produced around the globe annually comes from the development business, metal manufacturing has a serious function to play right here,” says Dr. Kanyilmaz. “The present manufacturing methods accessible will not be simply optimised, and there’s a lot of fabric wasted.

“For instance, in the course of the slicing and welding of metal plates. Additionally, utilizing standard building methods, plenty of materials is used the place it is not wanted and positioned in pointless spots.”

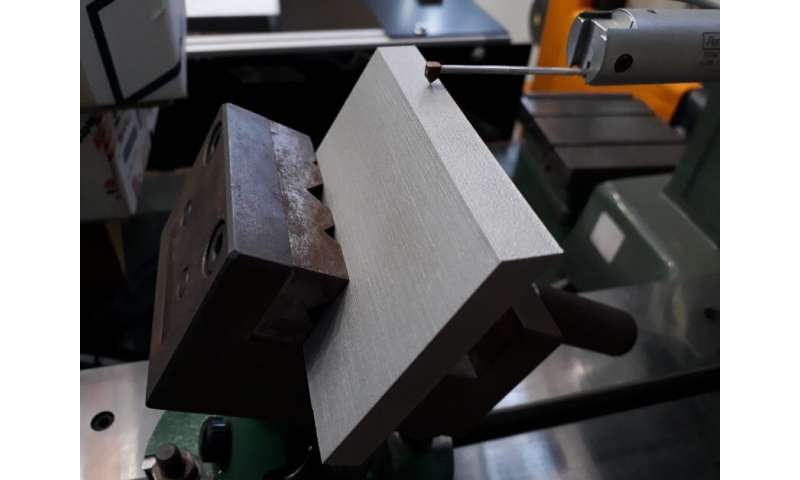

That is the place metallic 3D printing, or metallic additive manufacturing as it is usually recognized, is available in.

Printing customised parts and joints from scratch eliminates the manufacturing of scrap metallic within the course of that might in any other case end result as a byproduct of crafting elements from an present metal plate.

It can additionally permit for the optimisation of the manufacturing course of and larger flexibility on the a part of building firms, who will be capable of print sure parts on-site fairly than counting on transportation.

Metal 3D printing holds specific attraction, given its important nature to the development business, due to its excessive strength-to-weight ratio, tensile power, ductility, and flexibility, amongst different components.

The EU is at the moment the world’s second-largest metal producer after China, manufacturing greater than 170 million tons of the metallic yearly.

“After we discuss additive manufacturing in the meanwhile, there are already some very attention-grabbing outcomes in different industries…some small homes are being constructed through this technique with concrete, for instance,” says Dr. Kanyilmaz.

“The place metal comes into play, is in printing essential parts that may be built-in into bigger constructions. Metal is way extra resistant and ductile in comparison with different supplies. So, it gives extra alternatives to fabricate extra advanced geometries which might face up to larger stress and fatigue hundreds.”

“In any future the place 3D printing turns into mainstream within the building business, metal will preserve these benefits. That’s what makes creating additive manufacturing expertise on this space so engaging.”

Supplied by IMDEA Supplies

Quotation:

How metallic 3D printing can deliver change to the world’s most useful resource intensive business (2023, January 27)

retrieved 27 January 2023

from https://sciencex.com/wire-news/436252013/how-metal-3d-printing-can-bring-change-to-the-worlds-most-resour.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.