ARMOR Industrial Inks, (A2i), announces that its new range aqueous aqueous inks are now available for direct printing. Their white stability, washability and other properties are unparalleled by any other textile application.

New DTF Ink Range

A2i, a semi-industrial brand of ARMOR Print Solutions (an ARMOR GROUP Company), announces the launch its new range of aqueous aqueous inks for Direct To Film (DTF). The range is aimed at the textile industry and specifically cotton applications. It includes five colours: cyan, magenta and yellow. These aqueous coloured inks can be used with several EPSON printer heads. Lastly, these inks are OEKOTEX certified. Standard 100 by OEKOTEX is a global uniform system of testing methods, criteria, and limits for harmful chemicals, which allows the OEKOTEX test institutes to certify textile products as safe. Standard 100 by OEKOTEX – tested for harmful substances – is a label that can be applied to products like ARStyle Inks.

Tom Strähnz, Managing Director A2i Germany, comments “Our range of inks goes beyond functionality; they also cater to the creative needs of companies in the fashion wear industry. Our inks are a brilliant addition to any design, adding a splash of color and retaining the colors for a long time. They make designs more eye-catching and visually appealing. Our inks produce excellent results on cotton and synthetic cotton blend fabrics.

Superior washability, stability and durability

In addition to the four CMYK colours, A2i’s R&D team has focused on white, advancing the technological progress through the use of advanced water-based polymers.

Giovanni Manca, Director of Ink Development, says: “White in textile applications is essential.” As a backdrop on fabric, white plays a crucial role in bringing out the color. ARStyle white is more stable, so we gave it special attention. The preparation time for reprinting is also shortened. The white ink’s stability ensures a faster restart after a production break. “Whether there is a long or short break, our white ink will maintain a consistent performance to minimise disruptions to workflow.”

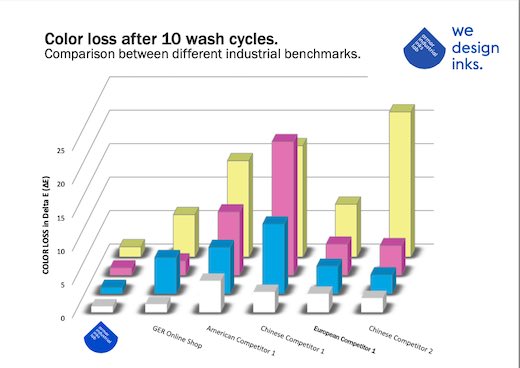

A2i also conducted tests in-house adapted from ISO 6330 – Textiles, Domestic Washing and Drying Methods for textile testing. And the results show that colour loss after 10 washes at 40°C for a 150min cycle is minimal compared to five competitors.

Tom Strähnz, Managing Director A2i Germany, concludes: “The properties of our inks allow the colors to stay vibrant for much longer, which not only meets a quality and aesthetic challenge, but also has an impact on sustainability. The consumer will be able keep the garment for longer. This is crucial in a climate where garment consumption is the leading source of greenhouse gas emissions.