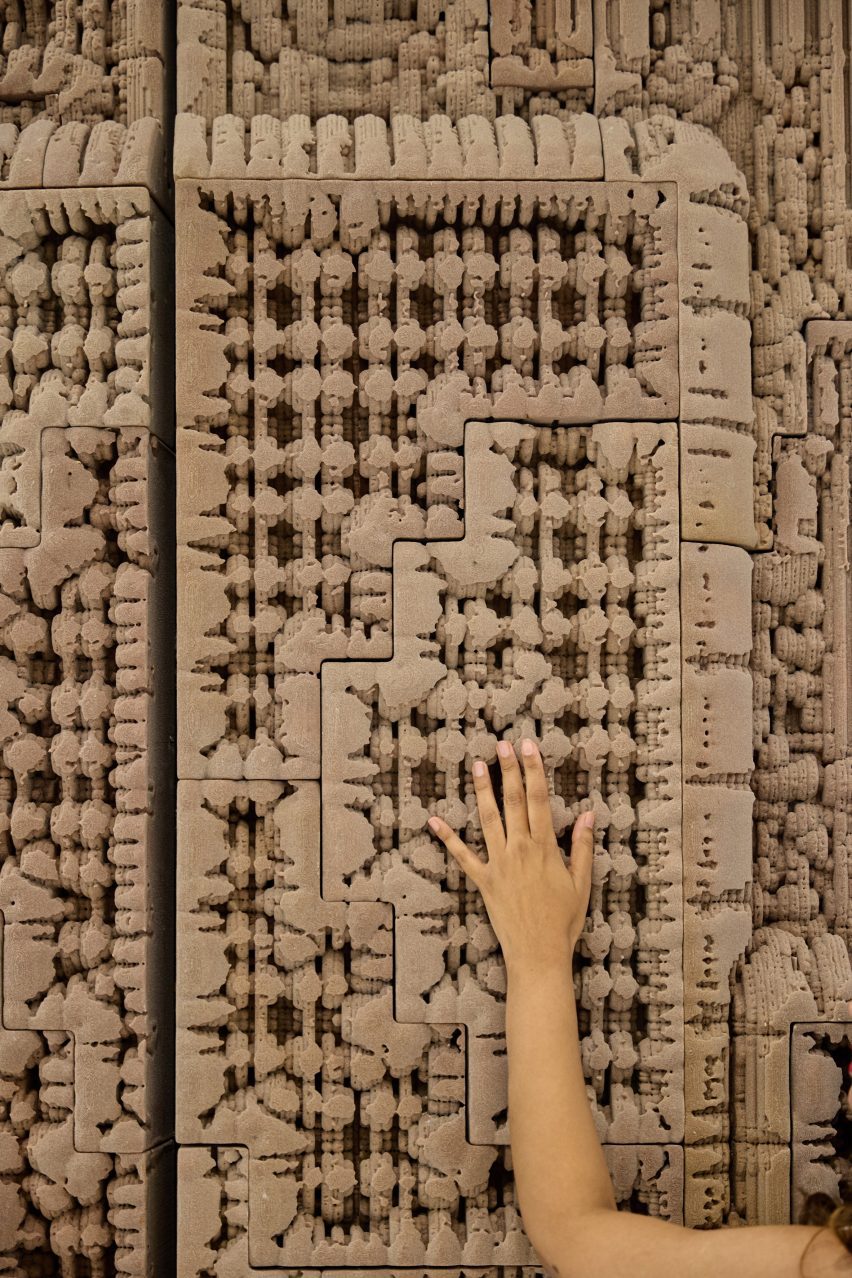

The Museum of the Future in Dubai has unveiled a six-metre-long 3D-printed wall produced from sand by architect and researcher Barry Wark.

Wark stated the challenge, known as Nadarra, is the “most intricate 3D-printed wall ever manufactured”.

He believes sand-printing expertise, which is already utilized in automobile manufacturing, might be a recreation changer for the development trade.

“In time, I envision we will create interiors, facades and even structural components with this expertise because of its load-bearing capabilities and potential sturdiness,” Wark instructed Dezeen.

A smaller model of Nadarra was first exhibited as a part of the Museum of the Future’s launch exhibition Tomorrow As we speak, curated by Gonzalo Herrero Delicado, which opened in February 2022.

The development has now been prolonged to a dimension of three-by-six metres for the museum’s everlasting assortment.

The wall has a novel aesthetic because of the intricate 3D textures that type its surfaces.

Wark used generative AI software program to design these 3D surfaces, emulating pure erosion processes.

The designer stated he wished to focus on how, within the face of the Anthropocene, the road between pure and human-made is more and more blurring.

“The challenge explores qualities of ambiguity in type, texture and materials that function between the pure and the artifactual, trying to focus on that these classes could not be so simply outlined,” he stated.

The wall was assembled from a sequence of 3D-printed “jigsaw panels”. These have been produced utilizing binder-jet printing, a course of that entails including a liquid binding agent into the skinny layers of printed particles.

Wark believes this type of 3D printing gives essentially the most potential in desert nations like these within the Center East.

“This expertise has the potential to bind collectively a wide range of sands and gravels into architectural components,” he defined.

“This has explicit relevance for the UAE as it’d enable the area to utilise native supplies within the design and development of their cities sooner or later, making a extra ecological constructing follow.”

In line with Wark, the wall will be floor down and reprinted as much as eight instances with out compromising its structural integrity.

When Nadarra was first proven in 2022, it was within the type of a planted wall. Preserved moss was put in in gaps throughout the floor, to recommend how actual crops might inhabit the wall in a pure surroundings.

The moss has since been eliminated, partly for causes referring to long-term upkeep within the museum surroundings.

Wark believes the design has extra resonance with out the crops, which he thinks might be construed as greenwashing.

“The wall celebrates the fantastic thing about nature within the UAE biome, which isn’t extremely vegetated,” he urged.

“I believe that is vital because it creates extra contextual approaches to ecological design and avoids the damaging trope of greenwashing in areas the place it may not be applicable.”

Wark will not be the one designer exploring the potential of sand-printing. Different constructed examples embrace an set up in Saudi Arabia by Precht and Mamou-Mani Architects.