The form, measurement and optical properties of third-dimensional nanostructures can now be simulated upfront earlier than they’re produced immediately with excessive precision on all kinds of surfaces.

Harald Plank from the Institute of Electron Microscopy and Nanoanalysis at TU Graz has been researching for over ten years how advanced, free-standing 3D architectures could be produced within the nanometre vary.

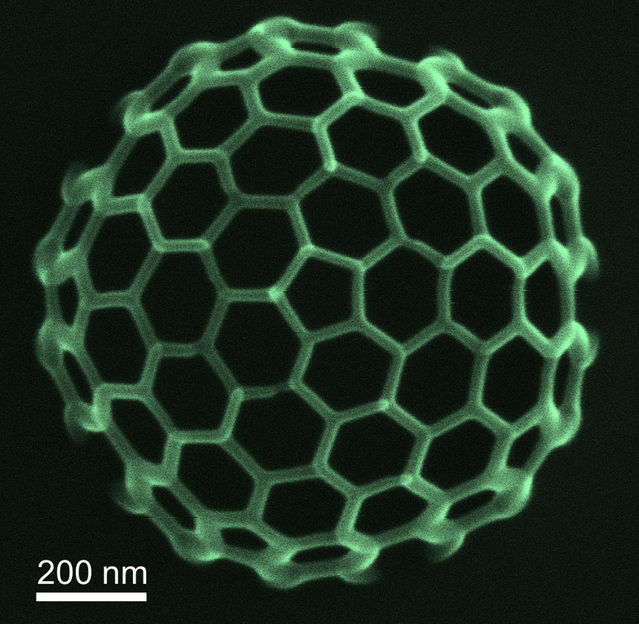

CDL DEFINE/TU Graz

For round 20 years, it has been attainable to switch surfaces through nanoparticles in order that they focus or manipulate gentle within the desired approach or set off different reactions. Such optically lively nanostructures could be present in photo voltaic cells and organic or chemical sensors, for instance. To be able to increase their vary of purposes, researchers on the Institute of Electron Microscopy and Nanoanalysis (Graz College of Know-how) and the Graz Centre of Electron Microscopy (ZFE) have been working for multiple decade on manufacturing not solely flat nanostructures, however particularly advanced, free-standing 3D architectures. The workforce led by Harald Plank, Verena Reisecker and David Kuhness has achieved two breakthroughs. It’s now attainable to exactly simulate the required styles and sizes of nanostructures upfront to attain the specified optical properties, which might then be precisely produced. They’ve additionally managed to fully take away chemical impurities, included throughout preliminary manufacturing with out negatively impacting the 3D nanoarchitectures.

Trial-and-error process turns into pointless

Till now, three-dimensional nanostructures required a time consuming trial-and-error course of till the product revealed the specified optical properties. This effort has lastly been eradicated. “The consistency between simulations and actual plasmonic resonances of a variety of nanoarchitectures could be very excessive,” explains Harald Plank. “This can be a big step ahead. The laborious work of the previous couple of years has lastly paid off.” The know-how is presently the one one on this planet that can be utilized to provide advanced third-dimensional buildings with particular person options smaller than 10 nanometres in a managed, single step process on virtually any floor. For comparability, the smallest viruses are round 20 nanometres in measurement. “The most important problem in recent times was to switch the 3D architectures into high-purity supplies with out destroying the morphology,” explains Harald Plank. “This growth leap allows new optical results and utility ideas because of the 3D side.” Nanoprobes or optical tweezers with sizes within the nanometre vary are actually inside attain.

Exactly managed electron beam

The researchers use targeted electron beam induced deposition to provide the nanostructures. The related floor is uncovered to particular gases beneath vacuum situations. A finely targeted electron beam splits the fuel molecules, whereupon elements of them change right into a strong state and cling to the specified location. “By exactly controlling beam actions and publicity occasions, we’re in a position to produce advanced nanostructures with lattice- or sheet-like constructing blocks in a single step”, explains Harald Plank. By stacking these nano-volumes on prime of one another, three-dimensional buildings can finally be constructed.

Unique publication

Verena Reisecker, David Kuhness, Georg Haberfehlner, Michele Brugger‐Hatzl, Robert Winkler, Anna Weitzer, David Loibner, Martina Dienstleder, Gerald Kothleitner, Harald Plank; “Spectral Tuning of Plasmonic Exercise in 3D Nanostructures through Excessive‐Precision Nano‐Printing”; Superior Useful Supplies, 2023-11