As aerospace expertise advances, Purdue College‘s analysis continues to push the boundaries of hypersonic journey. Leveraging cutting-edge 3D printing expertise, researchers on the Purdue Utilized Analysis Institute (PARI) have efficiently produced totally purposeful supersonic combustion ramjet (also called scramjets) prototypes. These revolutionary and highly effective engines have the potential to propel future plane at hypersonic speeds exceeding Mach 5.

Led by the Hypersonic Superior Manufacturing Know-how Middle (HAMTC) at Purdue, this breakthrough signifies a monumental leap ahead within the hypersonics business. It’s because the brand new scramjet design provides an economical and time-saving strategy to prototyping and manufacturing within the area.

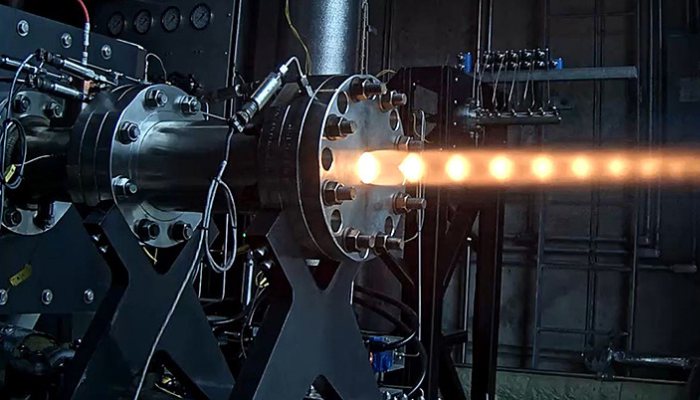

Scramjet at Purdue’s Maurice J. Zucrow Laboratories

Scramjets are essential within the aerospace business for his or her skill to maintain combustion at extremely excessive speeds, permitting plane to journey past Mach 2. Acquiring this pace is usually notably difficult, and as described by Nick Strahan, HAMTC senior take a look at engineer, the duty is akin to “lighting a candle in a hurricane,” as flames must be sustained at fast velocity. Nonetheless, with revolutionary combustor designs and environment friendly gas combustion strategies, Purdue researchers have overcome these challenges with the scramjet, paving the way in which for unprecedented developments in aerospace expertise.

The Function of Additive Manufacturing in Scramjet Growth

Among the many key components driving this innovation is Purdue’s utilization of 3D printing expertise, together with the GE Idea Laser X Line 2000R, famend as one of many world’s largest metallic laser powder mattress options, due to its capability of 160 liters. This massive-scale metallic printer not solely streamlines the manufacturing course of but in addition permits the creation of the extremely complicated designs wanted for the engines. Notably, the 2000R additionally minimizes half depend, thus optimizing efficiency whereas simplifying manufacturing, and permits for elevated weight discount whereas nonetheless sustaining full performance of the engines.

HAMTC’s government director, Michael Sangid, spoke on the success of this venture, stating, “The scramjet pilot venture is a good instance of our vertically built-in capabilities. We are able to take uncooked powder and switch it into consultant take a look at knowledge from a fielded prototype in a number of brief months. This leverages the flexibleness of additive manufacturing into the part’s design to extend effectivity.”

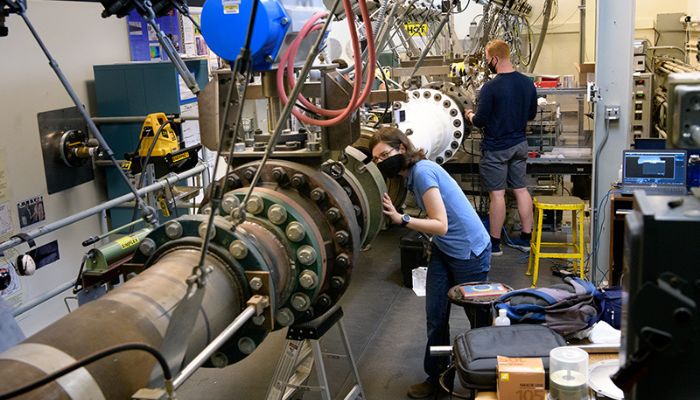

Purdue college students work inside Purdue’s Hypersonics and Utilized Analysis Facility.

Purdue’s hypersonic analysis carries important implications past technical developments, extending to nationwide safety and protection. The improved manufacturing pace and cost-efficiency not solely scale back bills but in addition handle the nation’s rising want for superior hypersonic applied sciences. Furthermore, by involving college students in all venture phases—from design to manufacturing and testing, this venture will assist foster a brand new technology proficient in extremely sought-after, superior hypersonic abilities to fulfill the rising business. You possibly can study extra about this venture by clicking right here.

What do you consider Purdue’s use of 3D printing for prototyping of scramjets? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly publication right here, the most recent 3D printing information straight to your inbox! You too can discover all our movies on our YouTube channel.

*All Photograph Credit: Purdue College