Researchers on the Massachusetts Institute of Know-how (MIT) have achieved a breakthrough that would remodel electronics manufacturing. Their profitable 3D printing of three-dimensional solenoids represents a big leap ahead in electronics manufacturing. Solenoids, comprised of a coil of wire wound round a magnetic core, function indispensable parts in a myriad of digital purposes. From essential medical units like dialysis machines and respirators to on a regular basis family home equipment resembling washing machines and dishwashers, solenoids play an important position in changing electrical power into mechanical work. Historically, manufacturing solenoids has required complicated methods.

The event of absolutely 3D-manufactured digital units at the moment poses appreciable challenges. Nonetheless, ongoing analysis marks a development in the direction of extra economical and fewer wasteful manufacturing methods. These enhancements may very well be used throughout many industries, with use even in area.

The Massachusetts Institute of Know-how (MIT)

3D Printed Electromagnets

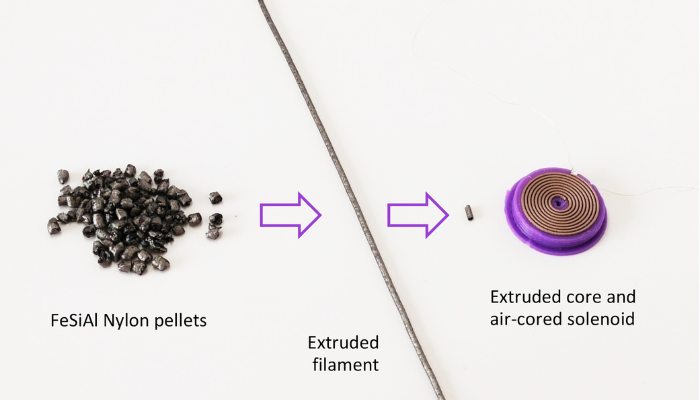

Conventional manufacture of solenoids includes the complicated meeting of various supplies, usually limiting the dimensions and form of the components. The usage of 3D printing, nevertheless, presents the potential for overcoming these constraints. MIT researchers, led by Luis Fernando Velásquez-García, have solved the issues related to materials compatibility by adapting their multi-material 3D printer to superimpose three totally different supplies: a dielectric materials serving as an insulator, a conductive materials forming {the electrical} coil, and a delicate magnetic materials making up the core. This adaptation facilitated the manufacturing of compact, single-piece solenoids, eliminating the potential for meeting errors.

By way of their experiments, the researchers completed the printing of an electromagnet with eight winding layers, organized in a spiral configuration. This modification to the printer allowed for the creation of extra compact but higher-performing solenoids. These outcomes confirmed {that a} 25 mm-diameter electromagnet made by 3D printing can face up to twice the electrical present and generate a magnetic subject thrice stronger than its conventionally manufactured equal.

Solenoids are made by layering three supplies: an insulator, a conductor for the coil, and a magnetic core.

Regardless of the preliminary funding in customized tools, utilizing 3D printed electromagnets has vital financial benefits over standard manufacturing strategies. This development may revolutionize manufacturing processes by minimizing waste and enhancing accessibility to important medical tools, resembling dialysis units, particularly in distant areas. The potential advantages of 3D printing lengthen past our planet, providing intriguing prospects for area exploration. With the aptitude to provide substitute digital parts on demand, this expertise may considerably minimize prices and time delays, presenting a sustainable answer important for prolonged area missions. Talking on these benefits, Luis Fernando Velásquez-García defined,

Along with making electronics cheaper on Earth, this printing {hardware} may very well be notably helpful in area exploration. For instance, as an alternative of transport substitute digital components to a base on Mars, which may take years and price hundreds of thousands of {dollars}, one may ship a sign containing recordsdata for the 3D printer.

What do you consider these 3D printed solenoids? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly e-newsletter right here, the newest 3D printing information straight to your inbox! It’s also possible to discover all our movies on our YouTube channel.

*All Picture Credit: Massachusetts Institute of Know-how (MIT)