As additive manufacturing continues to industrialize and advance, partnerships and collaborations turn out to be ever extra necessary. Take the case of CADvision and ETEC, a part of Desktop Metallic. The 2 have labored and grown collectively for almost seven years and are dedicated to serving to to advance polymer additive manufacturing for industrial purposes.

We spoke to the CEO of CADvision and the Head of Polymers in EMEA at Desktop Metallic, to be taught extra concerning the partnership between the businesses and the way they’re selling and accelerating DLP 3D printing in Europe.

Manuel Delgado (left) and Julien Markarian (proper)

3DN: Inform us just a little about your self and your connection to 3D printing?

JM: I’m Julien Markarian, the CEO of CADvision. CADvision is a distributer situated in France that has developed its expertise within the integration of additive manufacturing within the industrial, schooling/analysis and medical sectors during the last 25 years.

MD: I’m Manuel Delgado, RSM and Head of Polymers in EMEA at Desktop Metallic. I’ve 9 years of expertise of in additive manufacturing within the polymer trade protecting totally different supplies, tools applied sciences and holding numerous management positions.

3DN: What are the capabilities of ETEC’s industrial polymer machines? What sort of purposes can you could have for patrons?

JM: ETEC polymer machines are essentially the most superior obtainable available on the market. Because of industrial partnerships, ETEC machines are appropriate with very superior materials that can be utilized on platforms that supply excessive scalability and repeatability. ETEC is at the moment the one firm that may supply techniques which might be actually constructed for manufacturing, with nice construct volumes and excessive accuracy.

Totally different options from ETEC utilized by CADvision at their facility in Valence

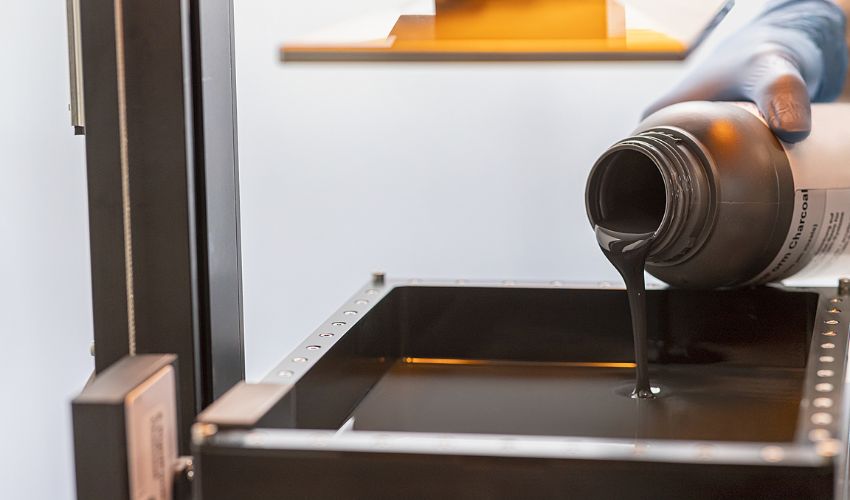

ETEC polymer machines have key differentiators in opposition to every other participant on the polymer market. Amongst these, the number of industrial-compatible resins and the standard of their administration, and the rising capability of the techniques (for instance with the newest Xtreme 8K, which affords an unprecedented construct quantity) are opening for actual huge purposes in all industrial markets.

3DN: What position does materials choice play? What are the advantages of utilizing ETEC for CADvision?

JM: Materials choice is vital for making additive manufacturing profitable, particularly for DLP. CADvision’s position, as integrator for its clients, is, amongst different issues, to coach on this choice, and hold updated on options and advantages of utilizing this or that materials. ETEC is by far essentially the most open expertise for supplies, and the portfolio is continually enlarging.

MD: Materials capabilities are a decisive issue within the enablement of any given utility. ETEC has optimised its providing by including top-class industrial supplies to its portfolio, cooperating with the world’s greatest materials suppliers and rising our personal materials growth capabilities, growing distinctive breakthrough options reminiscent of FreeFoam®, the primary true 3D printable foam.

Via ETEC and its options and supplies, it’s attainable for CADvision to make elements which might be appropriate for industrial purposes

3DN: Might you inform us extra about ETEC and CADvision?

JM: CADvision’s mission is to help its clients within the setup of additive manufacturing as a software for enhancing the manufacturing flexibility. Additive manufacturing is turning into a must have on high of extra conventional approaches because it permits shortcuts and novel design in an increasing number of tasks or current productions.

AM adoption requires very extremely expert help to get acceleration, potential customers not at all times being conscious of all of the potential of it to make it viable of their factories. identification and ROI estimation on every potential mission is vital, and it’s most likely what slows down adoption. Being supported by a professional associate is subsequently the important thing to success.

MD: Based in 2002, ETEC is a world chief in polymer 3D Printing expertise and authentic creator of the world’s first DLP printer. Our mission is to make 3D printing of end-use polymer elements accessible at scale to all engineers, designers and producers utilizing cost-competitive, high-speed and exceptional-quality 3D printing.

Elements on the Xtreme 8K 3D printer

3DN: How lengthy have you ever had this partnership? What have been the advantages?

JM: The DM/CADvision partnership began in 2017 with DM steel options. Quick adoption of the primary launched system (Studio) allowed CADvision to amass sturdy expertise on this new rising market. CADvision then loved the successive acquisitions made by the group, together with EnvisionTEC which was the inspiration for the brand new ETEC line.

CADvision selected ETEC and Desktop Metallic as one in all its most important companions as a result of they’re at the forefront of additive manufacturing techniques in a big subject of purposes. Earlier than the final decade, CADvision was primarily specializing in distributing 3D printers for the prototyping purposes in R&D facilities. The partnership with Desktop Metallic was key to switching from this small potential market to the true additive manufacturing market, which is far bigger, although tougher to grasp.

3DN: Why DLP? What are the benefits or difficulties of utilizing DLP in comparison with different AM processes?

The Professional XL from ETEC

JM: DLP is the perfect expertise for opening giant alternatives in additive manufacturing for resin-based elements which might be appropriate with industrial purposes. DLP is a really complementary strategy to plastic deposition because it brings totally different supplies and permits for high-quality elements appropriate with industrial use.

MD: DLP affords a novel set of benefits within the polymer 3D printing world: floor high quality, excessive function particulars and repeatability, however as a novel function of DLP: excessive throughput and scalability in comparison with different polymer applied sciences. As a draw back, like different resin-based applied sciences, it requires a publish processing workflow, which is correct now in a fast means of modernisation with computerized and semi-automatic options

3DN: Any final phrases for the reader?

JM: Selecting ETEC/Desktop Metallic and CADvision is a assure for the purchasers to make the additive manufacturing integration profitable, and by consequence see its use progress within the firm wherever it is sensible. You may be taught extra about us HERE.

DM: ETEC at the moment affords essentially the most complete tools options and materials providing for the commercial person. Along with that, we’ve just lately introduced our Co-Location Manufacturing & Information Switch, enabling customers worldwide to efficiently undertake DLP applied sciences at scale, working hand in hand with our workforce of consultants at our services. You may be taught extra about ETEC HERE.

What do you consider the partnership between CADvision and ETEC? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to join our free weekly e-newsletter right here for the newest 3D printing information straight to your inbox! You may as well discover all our movies on our YouTube channel.