Industrial metal 3D printer manufacturer AddUp and Dassault Aviation a French aerospace company have announced their partnership to push metal additive manufacturing processes from “prototyping” to “mass production” for aeronautics.

Both businesses agree that for the aeronautics industry’s to be competitive, it must address many issues including increasing global air traffic, a shrinking supply of materials, lighter and more efficient parts, the pursuit and enforcement of ever-more strict regulations and reliability. These problems can be solved by metal 3D printing in industrial production conditions. In this setting, the collaborative R&D project “AEROPRINT”, headed by Dassault Aviation, was established with the aid of a large number of partners, research institutions, academic institutions, and businesses, among them AddUp.

What exactly is the AEROPRINT initiative?

This 5-year project is designed to develop, qualify and incorporate a competitive preindustrial demonstrator of multimaterial metal additive manufacturing (Titanium and Aluminum), for the production advanced aeronautical parts certified in classes 2 and 3 over a five-year period. The Dassault Aviation facility in Argonay, Auvergne-Rhône-Alpes (France), has been designated as a pilot site for the integration of this process.

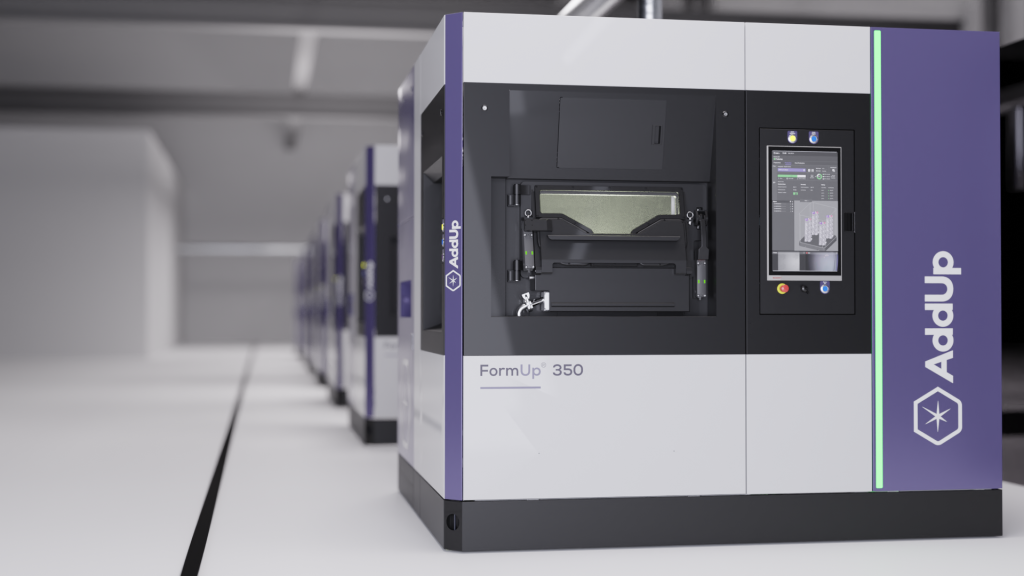

AddUp is responsible for creating a new production system that relies on interoperability as well as process automation. The aim is to assign the equipment while also making sure that the proper isolation and circulation are achieved for the materials chosen. AddUp experts are developing a new type enclosed enclosure that allows powder to enter one side and a tray with metal parts to exit the other. This future workshop will consist of two production units of four FormUp® 350 machines relying on powder bed fusion technology (L-PBF: Laser Powder Bed Fusion) as well as the finishing means required. For the same, two PBF machines from AddUp were selected.

Following a phase of combined development and research to discover all of the project’s requirements, AddUp is now working on the full-size model to verify and test the principles maintained, from mechanical design to autonomy, without forgetting the computer, which manages everything. AddUp Manager’s intuitive interface and super-fast trajectory generation engine allow you to create production file by accessing more than 250 modifiable variables as well as customizable fusion strategies. Monitoring is an important aspect of such projects. The AddUp Dashboards software will be used, and bricks will be added.

AddUp Dashboard allows users to quickly and easily analyze machine events, view production data in real time, monitor shop floor activity, and access other useful information. The software includes a pre-configured view that displays real-time progress, remaining time and current status. This software also allows users to view data from previous production runs and track production progress.

What can this automated workshop offer?

The two metal powders are loaded by an operator at a delivery station outside the workshop. Inside, an automated conditioning station takes over the production tray and inserts it into a mobile chamber known as a “jacket.” Depending upon the material, it is transferred in an inverted shuttle by an Automated Guided Vehicle (AGV) and then placed in each PBF machine. After printing is complete, the shuttle returns it to the depowdering station.

The same station will remove most of the powder that wasn’t fused during printing, and then recycle it before it is sent back for the next printing. After all powder is removed, the shuttle goes to the conditioning station. The tray containing the parts is pulled from the chamber, and taken to the parts drying and washing station. After the powder has been removed, the shuttle moves to the conditioning station. The tray containing the parts is taken out of its chamber and transported to the parts washing and drying station. Before the parts are allowed to leave the workshop, the tray that contains them is cleaned thoroughly and then handed over to the operator.

Automated workshops offer many advantages. From the point of HSE (Health, Safety, and Environment), the operators are not allowed to come in contact with the powder. The robotized enclosure is only used for maintenance. All other work is performed outside. The process can be repeated from an industrial perspective once it has been tested and validated.

This automated prototype workshop will be the basis for an industrial solution that can be used to deploy additive manufacturing machines in existing workshops. It will ensure the highest levels of safety and productivity.

Metal AM for aerospace

Previously, Falcontech, an aerospace manufacturing service provider, announced that it would ensemble its “Super AM Factory” with 50 Farsoon metal 3D printing systems. Chinese aerospace company Falcontech increased its manufacturing capability by installing 20 Farsoon machine before 2020. This allowed for large-scale production.

GE Aviation, a multi-national manufacturer of components and jet engines, was also the first to offer metal additive manufacturing (for commercial jet engine parts repairs). The firm’s Loyang facility in Singapore had become the world’s first maintenance, repair, and overhaul (MRO) facility to gain approval to utilize the technology for this purpose.

AM mass production and automation

3DQue, a Vancouver-based 3D printer startup, demonstrated last year the cost-effectiveness and efficiency of its Quinly 3D Printer Automation Upgrade on the Ultimaker S5. Initial test results show that the Quinly Ultimaker S5 upgrade reduces operator time by 90%, while also lowering the cost per piece by more than two-thirds. 3DQue believes the automation upgrade is a demonstration of the economics behind metal 3D printing for mass-production.

SoonSer is an industrial brand for 3D printers and consumables maker SoonSolid. The Mars Pro 3D printer series was designed to meet industrial mass production requirements. Mars Pro 600, 800, and 1600 SLA 3D Printers are included in this series. These printers have large expandable build volumes of 1600 x 800x 600mm and can be used for prototyping, manufacturing and precision casting, for use in automotive, art and architecture, as well medical applications.

For all details, follow this link Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry Newsletter Follow us on TwitterLike our page or send us an email Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you interested in a job within the additive manufacturing sector? Visit 3D printing jobs For a list of available roles in the industry.

Feature image: Dassault Falcon 20,G maritime patrol aircraft. Photo by Dassault.